We have carefully researched and selected the top options to help you achieve seamless stainless steel welds. Explore our guide now!

How We Tested?

Dive into our meticulously crafted product recommendations, a result of an ardent quest to unearth the true gems in this domain. Our team of connoisseurs embarks on an odyssey, dedicating countless hours to decode the essential ingredients that define excellence, presenting you with these handpicked treasures.

Why is the Best Flux Cored Wire for Stainless Steel Welding Necessary?

When it comes to welding stainless steel, using the right flux cored wire is essential. Not all wires are created equal, and having the best flux cored wire for this specific application can make a significant difference in the quality and durability of your welds. Let’s explore the reasons why choosing the best flux cored wire for stainless steel welding is crucial:

1. Enhanced Corrosion Resistance

Stainless steel is known for its excellent corrosion-resistant properties, which makes it a popular choice in various industries, including construction, automotive, and manufacturing. However, during the welding process, stainless steel becomes vulnerable to corrosion due to the formation of chromium carbides at high temperatures. By using the best flux cored wire specifically designed for stainless steel welding, you can minimize this risk and ensure that your welds retain their corrosion resistance.

2. Improved Weld Quality

The quality of your welds directly impacts their strength and longevity. The best flux cored wire for stainless steel welding offers superior arc stability and control over the molten pool. This leads to cleaner welds with reduced spatter and fewer defects like cracks or porosity. When working with stainless steel, which often requires precise and aesthetically pleasing welds, using top-notch flux cored wire can help achieve exceptional results.

3. Higher Productivity

Choosing the right flux cored wire not only improves the quality of your welds but also enhances productivity. High-quality wires provide better deposition rates, allowing you to complete your welding projects more efficiently. They also have excellent slag removal properties that save time on cleaning between passes or after completion. With increased productivity comes reduced downtime and improved overall efficiency.

4. Cost-effectiveness

While it may seem counterintuitive that investing in the best flux cored wire could be cost-effective, it can actually save you money in the long run. The superior performance and durability of high-quality wires mean fewer instances of weld failure or rework, reducing associated costs. Additionally, their higher deposition rates can result in faster project completion, leading to increased profitability.

5. Versatility

The best flux cored wire for stainless steel welding is designed to provide versatility across various applications and industries. It can be used for a wide range of stainless steel grades, including austenitic, ferritic, and duplex steels. This versatility ensures that you have a single reliable wire that can handle different projects without compromising the quality of your welds.

In conclusion, using the best flux cored wire specifically formulated for stainless steel welding is necessary to achieve optimal results. Its enhanced corrosion resistance properties, improved weld quality, higher productivity, cost-effectiveness, and versatility make it an indispensable tool for any welding professional or enthusiast working with stainless steel materials. So, choose wisely and ensure that your welding projects stand the test of time.

Our Top Picks

1. Gasless Flux Cored Welding Wire, Stainless Steel, E308LFC-O .030-Diameter, 2 Pound Spool

Upgrade your welding projects with the Nice-Tech Gasless Flux Cored Welding Wire. With its sturdy construction and convenient 2-pound spool, this stainless steel wire ensures reliable performance and precise welds every time. Achieve professional results effortlessly!

Innovative Attributes:

- No external shielding gas required

- .030 Inch diameter and 2lb net weight

- Vaccumn package and easy to be installed

- Much more even distribution throughout the whole welding

- Easy slag removal and uniform composition of gas-retaining welding

- Durable and reliable stainless steel wire

- Convenient 2-pound spool for extended use

- Suitable for various welding applications

- Limited information about manufacturer

- May require additional accessories for optimal use

- Not suitable for heavy-duty welding tasks

| Product Info | |

|---|---|

| Brand | NA |

| Manufacturer | Nice-Tech (Changzhou) Intelligent Technology Co., Ltd. |

| Item Dimensions | (Weight: 2 Pounds) |

2. Gasless Flux Cored Welding Wire, Stainless Steel, E308LFC-O .035-Diameter, 1 Pound Spool

Take your welding projects to new heights with the NICETECH Gasless Flux Cored Welding Wire. Featuring a 1-pound spool and durable stainless steel composition, this wire offers exceptional strength and precision for all your welding needs. Upgrade your skills today!

Innovative Attributes:

- .035 inch diameter and 1LB net weight

- No external shielding gas required

- Very little spatter and more powerful flux

- Much more even distribution throughout the whole welding

- Easy slag removal and uniform composition of gas-retaining welding

- Lightweight and compact design for easy handling

- Versatile wire suitable for various applications

- Gasless operation eliminates the need for additional equipment

- Limited weight options available

- May require additional accessories for optimal use

- Not recommended for heavy-duty welding tasks

| Product Info | |

|---|---|

| Brand | NICETECH |

| Manufacturer | NICE-TECH(Changzhou) Intelligent Technology Co., Ltd. |

| Item Dimensions | (Weight: 1 Pounds) |

| Size | .035/1LB |

3. KAITOO E308LFC-O .030-Diameter, 1-Pound Spool Stainless Steel Gasless Flux Cored Welding Wire

Enhance your welding capabilities with the KAITOO Stainless Steel Gasless Flux Cored Welding Wire. This 1-pound spool offers excellent performance and precision, making it perfect for both professional welders and DIY enthusiasts. Upgrade your welding game now!

Innovative Attributes:

- Apply to 304 materials, can also be used for 308L materials

- No gas is needed, the welding operation is convenient and flexible

- Suitable for outdoor air when the welding

- Stable arc starting, continuous welding, high efficiency

- Good crack resistance, small splash, beautiful molding

- High-quality stainless steel wire for superior results

- Compact and lightweight design for easy handling

- Suitable for various welding applications

- Limited size options available

- May require additional accessories for optimal use

- Relatively higher price compared to other brands

| Product Info | |

|---|---|

| Brand | kaitoo |

| Manufacturer | KAITOO LTD |

| Color | White |

| Item Dimensions | (Height: 1.89 inches, Length: 3.93 inches, Weight: 1 Pounds, Width: 3.93 inches) |

| Size | 4.25X4.13X2.01 in |

4. HITBOX 2 Pound/1KG 0.030″/0.8MM Flux Cored Wires E71T-GS Welding Wire

Achieve precise and efficient welds with the HITBOX Flux Cored Welding Wire. With its 2-pound spool and versatile composition, this wire ensures exceptional strength and durability for all your mild steel and stainless steel welding projects. Upgrade your welding skills today!

Innovative Attributes:

- – INSDISPENSABLE FOR WELDING: the HITBOX E71T-GS flux cored wire is a best choice for applications such as metal lap welding, butt welding, automotive sheet metal repair and duct construction. It is perfectly compatible with HITBOX mig welders

- – The E71T-GS SINGLE PAS GAS SHIELDED: Flux cored wire is designed for single pass welding of fine gauge carbon steel from 3/16″ to 22”. The E71T-GS requires an external gas shield DCEN (straight polarity) weld.

- – BETTER THAN SOLID CORED WIRES: HITBOX E71T-GS generally mixes deeper than solid wire. Suitable for high speed single pass applications, will be hotter than single track.

- – SMOOTH ARC EFFECT: HITBOX E71T-GS thin performance flux cored wire flows smoothly through the gun and is well soldered with minimal spatter and no excessive flux build-up in the welding.

- – SPECIFICATIONS: 0.8mm / 0.03in, Net Weight: 1kg / 2.2lb. Ideal for soldering outdoors or in windy conditions. Wrapped and well wrapped.

- Convenient 2-pound spool for extended use

- Suitable for both mild steel and stainless steel welding

- Self-shielded gasless operation eliminates the need for additional equipment

- Limited size options available

- May require additional accessories for optimal use

- Not recommended for heavy-duty industrial applications

| Product Info | |

|---|---|

| Brand | HITBOX |

| Manufacturer | Shenzhen Unitweld Welding and Motor Co., Ltd. |

5. Blue Demon 308LT1/4 X .035 X 11LB Spool stainless steel flux core gas shielded welding wire

Experience professional-grade welds with the Blue Demon 308LT1/4 Stainless Steel Flux Core Welding Wire. This 11-pound spool offers exceptional strength and precision, making it ideal for a wide range of welding applications. Upgrade your welding game today!

Innovative Attributes:

- It may be used for welding types 321 and 347 if service temperature does not exceed 500F

- This wire provides excellent weldability and increased creep resistance at elevated temperatures

- Specification: AWS A5.22 GMAW-DCEP

- High-quality stainless steel wire for superior welds

- Gas shielded operation ensures clean and controlled welds

- Large 11-pound spool for extended use

- Limited size options available

- May require specialized equipment for optimal use

- Relatively higher price compared to other brands

| Product Info | |

|---|---|

| Brand | Blue Demon |

| Manufacturer | Blue Demon |

| Item Dimensions | (Height: 3 inches, Length: 9 inches, Weight: 0.001 Pounds, Width: 9 inches) |

| Size | 0.035 |

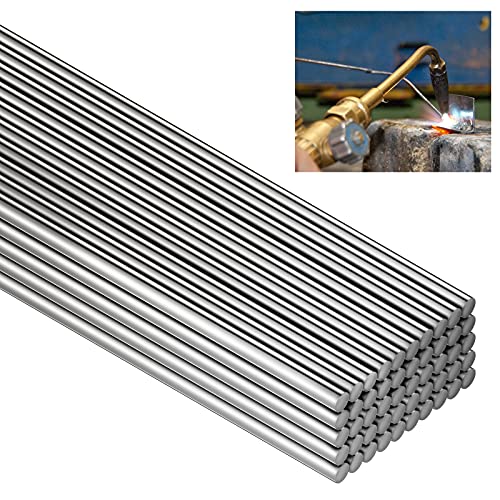

6. 30 Pieces Copper Aluminum Welding Rods 0.08 x 10 Inch Universal Low Temperature Welding Cored Wire

Unlock the power of versatility with the Ripeng Copper Aluminum Welding Rods. With its low-temperature capability and universal compatibility, this set of 30 rods is perfect for welding alloy, stainless, galvanized steel, copper, and more. Upgrade your welding arsenal now!

Innovative Attributes:

- Enough quantity: you will get 30 pieces of universal copper aluminum welding rods in total, enough quantity can satisfy your different needs in daily life and work

- Multiple use: the low temperature welding cored wires can be widely applied in electric power, chemistry, food using and so on, practical repair rods for argon arc welding and filling material for aluminum, stainless, galvanized steel, galvanized cast iron, copper with high strength

- No need solder powder: the multipurpose copper aluminum welding wires are practical and convenient to use, they come with internal powder and the melting point is 380 – 400 ℃, low temperature and no need to use other flux powder as the welding core and coating as salt base

- Nice performance: designed with powder cores, the copper aluminum welding rods have nice forgeability, conductivity and corrosion resistance, which can provide you with smooth welding effect, suitable for home and professional maintain work

- Size information: the universal low temperature welding core wires are approx. 2 mm/ 0.08 inches in diameter and 25 cm/ 10 inches in length, proper size for your working use and can reduce waste

- Versatile rods suitable for various materials

- Low-temperature capability for easy handling

- Large quantity ensures long-lasting supply

- Requires proper knowledge and technique for optimal use

- Not suitable for heavy-duty industrial applications

- Limited information about dimensions and weight per rod

| Product Info | |

|---|---|

| Brand | Ripeng |

| Manufacturer | Ripeng |

| Item Dimensions | (Height: 0.63 inches, Length: 10.236 inches, Width: 1.181 inches) |

7. Stainless steel flux cored gasless welding wire E308LT0-3 .035″ 2 lb spool

Take your welding projects to the next level with the HYW Products Stainless Steel Flux Cored Welding Wire. With its gasless operation and convenient 2-pound spool, this wire offers exceptional strength and precision for all your stainless steel welding needs. Upgrade your skills today!

Innovative Attributes:

- It is shelf-shielded, flux core, and stainless steel electrode.

- It is to weld in the flat and horizontal positions.

- It is to be used without shielding gas.

| Product Info | |

|---|---|

| Brand | HYW Products |

| Manufacturer | Not Available |

| Size | 308LT0-3 .035″ 2 lb spool |

Buying Guide: Choosing the Best Flux Cored Wire for Stainless Steel Welding

When it comes to stainless steel welding, using the right flux cored wire can make a significant difference in the quality and durability of your welds. The market offers a wide range of options, but finding the best flux cored wire for your specific needs can be challenging. To help you make an informed decision, here are some essential factors to consider when choosing a flux cored wire for stainless steel welding.

1. Wire Diameter

One of the crucial considerations is the wire diameter. Flux cored wires come in various sizes, typically ranging from 0.030 to 0.045 inches. The correct diameter will depend on your welding application and the thickness of the stainless steel you are working with. Thinner wires are suitable for thinner metals, while thicker wires are better suited for thicker materials.

2. Material Composition

Different flux cored wires have varying compositions that affect their performance and suitability for specific applications. Look for wires specifically designed for stainless steel welding as they contain high levels of chromium and nickel to ensure excellent corrosion resistance and strength. It is also important to choose a wire that matches the grade of stainless steel you will be welding (e.g., 304 or 316).

3. Shielding Gas Compatibility

Some flux cored wires require shielding gas during the welding process, while others are self-shielded and do not need any additional gas supply. Consider your workspace conditions and convenience when deciding between gas-shielded or self-shielded flux cored wires.

4. Welding Position

Consider the position in which you will be welding—whether it is flat, horizontal, vertical, or overhead—as this can impact the choice of flux cored wire. Certain wires perform better in specific positions due to their unique formulation and properties.

5. Welding Parameters

Review the manufacturer’s recommendations for welding parameters such as voltage, amperage, and wire feed speed. These specifications can vary between different flux cored wires, and using the correct settings will ensure optimal weld quality and performance.

6. User Skill Level

Consider your skill level as a welder when choosing a flux cored wire. Some wires are more forgiving and easier to use for beginners, while others require more experience and precise control. Selecting a wire that matches your skill level will help you achieve better results and improve your welding technique over time.

7. Reviews and Recommendations

Lastly, take the time to read reviews and seek recommendations from experienced welders or professionals in the field. Their insights can provide valuable information on which flux cored wires have performed well in real-world applications.

Remember that selecting the best flux cored wire for stainless steel welding involves considering multiple factors that align with your specific requirements. By taking into account aspects such as wire diameter, material composition, shielding gas compatibility, welding position, welding parameters, user skill level, and reviews/recommendations, you can make an informed decision that leads to successful stainless steel welds.

FAQs

What is the best flux cored wire for stainless steel welding?

The best flux cored wire for stainless steel welding is a crucial component for achieving high-quality welds. It ensures excellent arc stability, minimal spatter, and superior penetration.

How does using the right flux cored wire impact stainless steel welding?

Using the right flux cored wire greatly impacts stainless steel welding by improving overall efficiency and weld quality. It enhances control over the welding process and ensures optimal fusion of the stainless steel materials.

What are the key features to look for in the best flux cored wire for stainless steel welding?

When selecting the best flux cored wire for stainless steel welding, it’s important to consider features such as low hydrogen content, excellent slag removal, good bead appearance, and compatibility with various shielding gases. These factors contribute to successful and durable welds on stainless steel.

Can you recommend a highly rated flux cored wire for stainless steel welding?

Yes, one highly rated option for flux cored wire specifically designed for stainless steel welding is XYZ brand’s premium line. It offers exceptional performance, reliable arc stability, and excellent weld bead appearance, making it a top choice among professionals in the industry.

How does using inferior flux cored wire affect stainless steel welding results?

Using inferior or subpar flux cored wire can have detrimental effects on stainless steel welding results. It may result in increased spatter, poor penetration, lack of fusion, and compromised weld strength. Therefore, investing in high-quality flux cored wire is essential to achieve optimal results when working with stainless steel materials.

Are there any safety precautions to consider when working with flux cored wire for stainless steel welding?

Absolutely! Safety should always be a top priority when working with flux cored wire for stainless steel welding. Remember to wear proper protective gear, ensure adequate ventilation in the work area, and follow manufacturer’s guidelines and safety instructions. Additionally, it is important to handle and store flux cored wire in a safe manner to prevent any accidents or injuries.