Find top-quality options that guarantee strong and durable welds. Whether you’re a professional welder or a DIY enthusiast, we have got you covered with our carefully curated list of the best products available on the market. Discover the perfect welding wire to achieve flawless stainless steel welds with ease and efficiency.

How We Tested?

Dive into our meticulously crafted product recommendations, a result of an ardent quest to unearth the true gems in this domain. Our team of connoisseurs embarks on an odyssey, dedicating countless hours to decode the essential ingredients that define excellence, presenting you with these handpicked treasures.

Why the Best Flux Core Welding Wire for Stainless Steel is Necessary?

When it comes to welding stainless steel, using the right type of welding wire is crucial. The best flux core welding wire specifically designed for stainless steel can make a significant difference in the quality and durability of your welds. In this blog section, we will explore the necessity of using the best flux core welding wire for stainless steel projects.

Importance of Choosing the Right Welding Wire

Enhanced Corrosion Resistance: Stainless steel is known for its excellent corrosion resistance properties. However, during the welding process, regular carbon steel welding wires can introduce impurities, reducing the corrosion resistance of stainless steel joints. The best flux core welding wire formulated for stainless steel ensures minimal contamination, preserving the metal’s corrosion-resistant properties.

Improved Strength and Durability: Stainless steel applications often require high strength and durability. By selecting a premium flux core welding wire designed specifically for stainless steel, you can achieve stronger welds that withstand heavy loads and vibrations over time.

Protection Against Heat Affected Zone (HAZ) Sensitization: Welding heat can cause sensitization in stainless steel, leading to reduced corrosion resistance and potential cracking issues. Using a high-quality flux core welding wire minimizes HAZ sensitization risks by providing optimal chemical composition that matches stainless steel requirements.

Simplified Process and Increased Efficiency: The best flux core welding wires are designed to provide smooth arc stability, making them easier to handle during the welding process. This enhanced control allows welders to work more efficiently, resulting in improved productivity and reduced downtime.

Versatility in Applications: Different projects may require varying levels of performance from welded joints. The best flux core welding wires offer versatility in terms of their suitability for various types and thicknesses of stainless steel materials. Whether you are working on thin sheets or thick pipes, having a reliable welding wire ensures consistent and high-quality results.

Certified Quality Assurance: Premium flux core welding wires for stainless steel often undergo rigorous testing and adhere to industry standards. By selecting a reputable brand or product, you gain the assurance of using a high-quality welding wire that meets the necessary specifications for your stainless steel welding projects.

Conclusion

In summary, utilizing the best flux core welding wire specifically designed for stainless steel is essential for achieving optimal results in terms of corrosion resistance, strength, durability, HAZ protection, process efficiency, versatility, and certified quality assurance. Investing in a reliable welding wire tailored to stainless steel applications will not only improve the integrity of your welds but also ensure long-term performance and customer satisfaction.

Our Top Picks

1. NA Gasless Flux Cored Welding Wire, E308LFC-O .030-Diameter, 2 Pound Spool – High-Quality Welds Every Time!

Get high-quality welds with NA Gasless Flux Cored Welding Wire. With a 2-pound spool and .030-inch diameter, it’s convenient to use and provides excellent performance. The silver color adds a sleek touch to your welding projects.

Innovative Attributes:

- No external shielding gas required

- .030 Inch diameter and 2lb net weight

- Vaccumn package and easy to be installed

- Much more even distribution throughout the whole welding

- Easy slag removal and uniform composition of gas-retaining welding

- Convenient 2-pound spool size

- Excellent welding performance

- Sleek silver color adds aesthetic appeal

- Limited availability in other diameter options

- May require additional equipment for gasless welding

- Not suitable for all types of metals

| Product Info | |

|---|---|

| Brand | NA |

| Manufacturer | Nice-Tech (Changzhou) Intelligent Technology Co., Ltd. |

| Item Dimensions | (Weight: 2 Pounds) |

2. NICETECH Gasless Flux Cored Welding Wire, E308LFC-O .035-Diameter, 1 Pound Spool – Perfect for Precise Welding Jobs!

Achieve precise welding results with NICETECH Gasless Flux Cored Welding Wire. The .035-inch diameter and 1-pound spool make it ideal for intricate welding jobs that require accuracy and attention to detail.

Innovative Attributes:

- .035 inch diameter and 1LB net weight

- No external shielding gas required

- Very little spatter and more powerful flux

- Much more even distribution throughout the whole welding

- Easy slag removal and uniform composition of gas-retaining welding

- Suitable for precise welding jobs

- Compact 1-pound spool size

- Provides excellent weld quality

- Limited availability in other diameter options

- May not be suitable for heavy-duty welding projects

- Requires proper adjustment of settings for optimal results

| Product Info | |

|---|---|

| Brand | NICETECH |

| Manufacturer | NICE-TECH(Changzhou) Intelligent Technology Co., Ltd. |

| Item Dimensions | (Weight: 1 Pounds) |

| Size | .035/1LB |

3. Blue Demon 308LT1/4 X .035 X 11LB Spool, Gas Shielded Stainless Steel Welding Wire – Professional Grade Performance!

Experience professional-grade performance with the Blue Demon 308LT1/4 Gas Shielded Stainless Steel Welding Wire. With an 11-pound spool and .035-inch size, it’s perfect for demanding welding projects. Get precise and high-quality welds every time.

Innovative Attributes:

- It may be used for welding types 321 and 347 if service temperature does not exceed 500F

- This wire provides excellent weldability and increased creep resistance at elevated temperatures

- Specification: AWS A5.22 GMAW-DCEP

- Professional-grade performance

- Suitable for demanding welding projects

- Precise and high-quality welds

- Limited availability in other spool sizes

- Requires additional equipment for gas shielded welding

- Higher price compared to other options

| Product Info | |

|---|---|

| Brand | Blue Demon |

| Manufacturer | Blue Demon |

| Item Dimensions | (Height: 3 inches, Length: 9 inches, Weight: 0.001 Pounds, Width: 9 inches) |

| Size | 0.035 |

4. PGN Flux Core MIG Wire – E71T-11-0.030 Inch, 10 Pound Spool – Low Splatter, Versatile Welding Solution!

Achieve low splatter welding with the PGN Flux Core MIG Wire. The E71T-11 wire is versatile and can be used for all position arc welding as well as outdoor applications. With a 10-pound spool, you’ll have plenty of wire to tackle various projects.

Innovative Attributes:

- Welding Made Quick and Easy … Breeze through your welding project with ease with PGN flux core MIG welding wire. No need for shielding gas. The flux filling acts as a shielding agent to create beautiful welds; perfect for use outdoors.

- Do Your Best Work … Color all your clients impressed with the precision and arc control of the E71T-11 gasless MIG welder wire. You’ll love the low splatter whether you’re performing single or multi-pass welds. Great for T-joints, butt welds & lap welds.

- Unlock a World of Versatility … Professional welder, metalworking hobbyist, or DIY enthusiast, this gasless MIG wire gives you the freedom to work on multiple projects. It has a 0.030″ diameter.

- Get Value for Your Money … Save big without sacrificing on quality. Our flux core welding wire .030 comes in a 10-pound spool at a fraction of the cost. And unlike others that are haphazardly packed, we package ours with care to prevent annoying tangles.

- Quality You Can Trust … Based in South Florida, we take great pride in offering MIG welding accessories that conform to the highest standards. Check out our collection of products and upgrade your business or passion project with uncompromising quality.

- Low splatter welding solution

- Versatile for different welding positions and outdoor use

- Ample amount of wire with a 10-pound spool size

1.Limited availability in other diameter options

- May not be suitable for precise welding jobs

- Requires proper adjustment of settings for optimal results

| Product Info | |

|---|---|

| Brand | PGN Bearings |

| Manufacturer | PGN Bearings |

| Item Dimensions | (Height: 2 inches, Length: 8 inches, Width: 8 inches) |

5. Blue Demon 309LT1/4 X .035 X 11LB Spool, Gas Shielded Stainless Steel Welding Wire – Top-Notch Performance Guaranteed!

Get top-notch welding performance with the Blue Demon 309LT1/4 Gas Shielded Stainless Steel Welding Wire. With an 11-pound spool and .035-inch size, it’s perfect for versatile welding applications. Achieve high-quality welds with ease.

Innovative Attributes:

- It is also used for dissimilar weld joints between high strength, mild steels and low alloyed QT steels

- Specification: AWS A5.22 GMAW-DCEP

- AWS classification E309LT1-1/-4

- Top-notch welding performance

- Suitable for versatile welding applications

- Provides high-quality welds with ease

1.Limited availability in other spool sizes

- Requires additional equipment for gas shielded welding

- Higher price compared to other options

| Product Info | |

|---|---|

| Brand | Blue Demon |

| Manufacturer | Blue Demon |

| Item Dimensions | (Height: 3 inches, Length: 9 inches, Weight: 0.01 Pounds, Width: 9 inches) |

| Size | 0.035 |

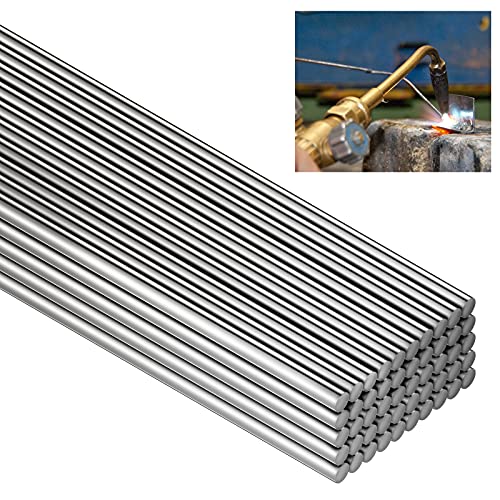

6. 30 Pieces Copper Aluminum Welding Rods, Universal Low Temperature Repair Rods – Perfect for Various Metal Welding!

Experience the versatility of the Ripeng Copper Aluminum Welding Rods. With 30 pieces and a low temperature requirement, they are perfect for various metal welding jobs including alloy, stainless steel, galvanized steel, and copper repairs.

Innovative Attributes:

- Enough quantity: you will get 30 pieces of universal copper aluminum welding rods in total, enough quantity can satisfy your different needs in daily life and work

- Multiple use: the low temperature welding cored wires can be widely applied in electric power, chemistry, food using and so on, practical repair rods for argon arc welding and filling material for aluminum, stainless, galvanized steel, galvanized cast iron, copper with high strength

- No need solder powder: the multipurpose copper aluminum welding wires are practical and convenient to use, they come with internal powder and the melting point is 380 – 400 ℃, low temperature and no need to use other flux powder as the welding core and coating as salt base

- Nice performance: designed with powder cores, the copper aluminum welding rods have nice forgeability, conductivity and corrosion resistance, which can provide you with smooth welding effect, suitable for home and professional maintain work

- Size information: the universal low temperature welding core wires are approx. 2 mm/ 0.08 inches in diameter and 25 cm/ 10 inches in length, proper size for your working use and can reduce waste

- Versatile for various metal welding jobs

- Low temperature requirement

- Ample quantity with 30 pieces included

1.Limited availability in other diameter options

- May require additional equipment or materials for certain metals

- Not suitable for heavy-duty or large-scale projects

| Product Info | |

|---|---|

| Brand | Ripeng |

| Manufacturer | Ripeng |

| Item Dimensions | (Height: 0.63 inches, Length: 10.236 inches, Width: 1.181 inches) |

7. PGN Flux Core MIG Wire – E71T-11-0.030 Inch, 2 Pound Spool – Easy-to-Use Mild Steel Welding Wire!

Make your welding projects a breeze with the PGN Flux Core MIG Wire. The E71T-11 wire is gasless and designed for mild steel welding. With a 2-pound spool, it’s convenient to use and provides low splatter

Innovative Attributes:

- Welding Made Quick and Easy … Breeze through your welding project with ease with PGN flux core MIG welding wire. No need for shielding gas. The flux filling acts as a shielding agent to create beautiful welds; perfect for use outdoors.

- Do Your Best Work … Color all your clients impressed with the precision and arc control of the E71T-11 gasless MIG welder wire. You’ll love the low splatter whether you’re performing single or multi-pass welds. Great for T-joints, butt welds & lap welds.

- Unlock a World of Versatility … Professional welder, metalworking hobbyist, or DIY enthusiast, this gasless MIG wire gives you the freedom to work on multiple projects. It has a 0.030″ diameter.

- Get Value for Your Money … Save big without sacrificing on quality. Our flux core welding wire .030 comes in a 2-pound spool at a fraction of the cost. And unlike others that are haphazardly packed, we package ours with care to prevent annoying tangles.

- Quality You Can Trust … Based in South Florida, we take great pride in offering MIG welding accessories that conform to the highest standards. Check out our collection of products and upgrade your business or passion project with uncompromising quality.

| Product Info | |

|---|---|

| Brand | PGN Bearings |

| Manufacturer | PGN Bearings |

| Item Dimensions | (Height: 2 inches, Length: 4.5 inches, Width: 4.5 inches) |

Buying Guide: How to Choose the Best Flux Core Welding Wire for Stainless Steel

When it comes to welding stainless steel, using the right flux core welding wire is crucial. The choice of welding wire can greatly impact the quality and durability of your welds. To ensure you select the best flux core welding wire for stainless steel, consider the following factors:

1. Wire Type

There are different types of flux core welding wires available in the market, each designed for specific applications. For stainless steel welding, look for wires labeled as "flux core stainless steel" or "stainless steel gasless flux core." These wires are specifically formulated to provide excellent corrosion resistance and strength when used on stainless steel.

2. Wire Diameter

The diameter of the welding wire plays a significant role in achieving optimal results. Thinner wires (e.g., 0.030-inch) work well for thinner materials and provide better control, while thicker wires (e.g., 0.045-inch) are suitable for thicker materials and offer higher deposition rates. Consider the thickness of the stainless steel you’ll be working with and choose a wire diameter accordingly.

3. Welding Position

Consider the position in which you’ll be welding—whether it’s flat, horizontal, vertical, or overhead—as this can affect how well certain wires perform. Some flux core wires are specifically designed to handle certain positions better than others. Check if the wire you’re considering is suitable for your intended welding position.

4. Shielding Gas Availability

One advantage of using flux core welding wire is that it eliminates the need for an external shielding gas like pure argon or a mixture of argon and CO2. However, some flux core wires may still require a shielding gas for improved performance or specific applications. Ensure that the chosen wire either doesn’t require any shielding gas or that the required gas is readily accessible to you.

5. Quality and Brand Reputation

Always opt for flux core welding wires from reputable brands known for their quality products. Check customer reviews and ratings to get an idea of the wire’s performance, reliability, and overall satisfaction. Trustworthy brands often provide consistent wire composition, resulting in better welds and reduced chances of defects.

6. Wire Storage and Handling

Proper storage and handling of flux core welding wire is crucial to maintain its effectiveness. Look for wires that come with proper packaging or spools to prevent moisture absorption, which can negatively impact weld quality. Additionally, ensure you store the wire in a dry environment away from extreme temperatures or humidity.

By considering these factors during your selection process, you’ll be able to choose the best flux core welding wire for stainless steel that suits your specific needs and ensures high-quality welds. Remember, selecting the right welding wire is essential for achieving strong and durable stainless steel welds that meet your requirements.

FAQs

What is the best flux core welding wire for stainless steel?

The best flux core welding wire for stainless steel is determined by factors like material thickness, desired weld appearance, and specific application requirements. It’s recommended to consult with professionals or refer to trusted welding product reviews to find the most suitable option.

How can I identify the top-quality flux core welding wire for stainless steel?

Identifying high-quality flux core welding wire involves considering factors such as brand reputation, AWS classification, diameter consistency, and spatter reduction capabilities. Conducting thorough research and seeking recommendations from experienced welders can help you make an informed choice.

Are there any specific brands known for producing the best flux core welding wire for stainless steel?

While there are several reputable brands in the market, it’s difficult to pinpoint a single brand as the absolute best for flux core welding wire for stainless steel. Some reliable options include Lincoln Electric, Hobart, Blue Demon, and Forney Industries. Each brand offers a range of products suitable for different applications and preferences.

Can you recommend a cost-effective yet reliable flux core welding wire for stainless steel?

Yes! For those seeking a cost-effective but reliable option, the Flux Core Stainless Steel Welding Wire by INETUB is worth considering. It offers excellent weldability and produces clean welds with minimal spatter at an affordable price point. Remember to match it with your specific project requirements before purchasing.

What diameter of flux core welding wire should I choose for working on stainless steel projects?

The choice of diameter depends on various factors such as base metal thickness and amperage settings. Generally, 0.030-inch or 0.035-inch diameters are commonly used for most stainless steel applications with standard MIG guns. However, it’s crucial to refer to your welding machine’s specifications and relevant guidelines for precise recommendations.

Are there any safety precautions I should be aware of when using flux core welding wire for stainless steel?

Absolutely! When working with flux core welding wire for stainless steel, it’s important to wear appropriate personal protective equipment (PPE) such as welding gloves, a welding helmet with a darkened lens, and flame-resistant clothing. Additionally, ensure proper ventilation in your workspace and follow all safety instructions provided by the manufacturer.